Detailed information

Deep groove ball bearing for high temperature applications

Single row deep groove ball bearings for high temperature applications are designed for challenging operating conditions, with certain variants being capable of performing at temperatures as high as 350 °C (660 °F). They have increased radial internal clearances and use graphite-based lubricants that are optimized for operation at high temperatures. The entire surface of the bearings are manganese phosphate treated, which enhances adhesion of the lubricant to the metal and improves their running-in properties. As with deep groove ball bearings generally, they are particularly versatile, accommodate radial and axial loads in both directions, and are easy to mount.

Optimized for operation at high temperatures – up to 350 °C (660 °F)

Easily swapped with grease-lubricated bearings of corresponding ISO dimensions

Increased reliability, reduced complexity and decreased environmental impact

Typical benefits of single row deep groove ball bearings

| Running in required | Yes |

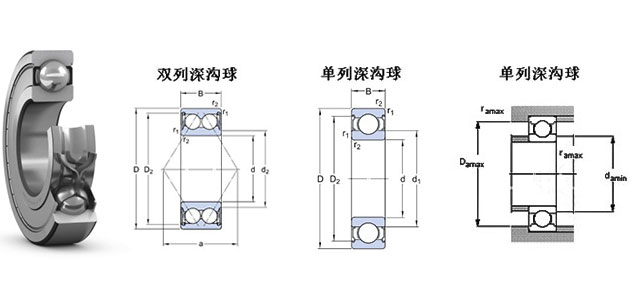

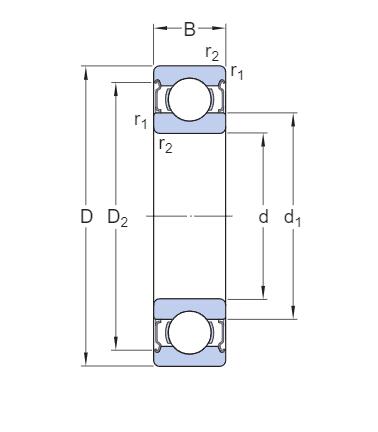

Dimensions

| d | 2.953 in | Bore diameter |

|---|---|---|

| D | 4.528 in | Outside diameter |

| B | 0.787 in | Width |

| d1 | ≈3.459 in | Shoulder diameter inner ring |

| D2 | ≈4.13 in | Recess diameter outer ring shoulder |

| r1,2 | min.0.043 in | Chamfer dimension |

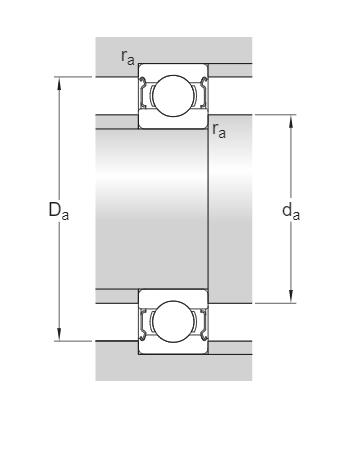

Abutment dimensions

| da | min.3.189 in | Abutment diameter shaft |

|---|---|---|

| da | max.3.457 in | Abutment diameter shaft |

| Da | max. 4.291in | Abutment diameter housing |

| ra | max.0.039 in | Fillet radius |

7 531 lbf 170 r/min max.482 °FCalculation data

Basic static load rating C0 Limiting speed Operating temperature T